Achieving Superior Do With In-Mold Decorations in Production

Grasping In-Mold Decorations: Methods, Patterns, and Ideal Practices for Optimum Outcomes

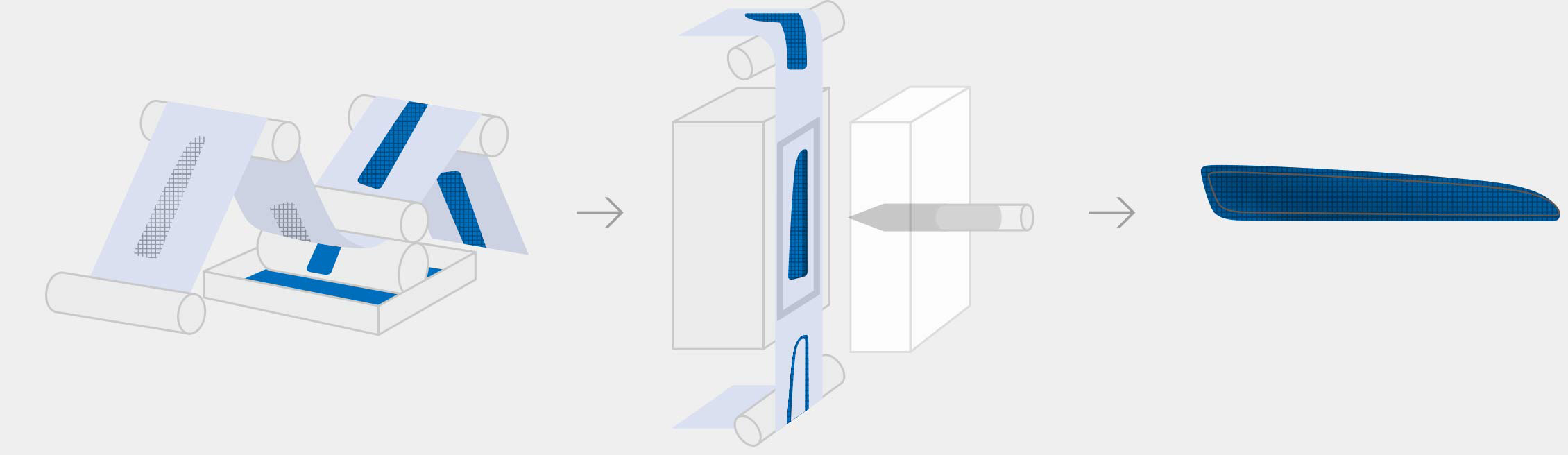

In the world of manufacturing, the art of in-mold decorations stands as an essential facet of product layout and manufacturing. In-Mold Decorations. By diving into the approaches, patterns, and finest methods that underpin successful in-mold design processes, services can unlock a world of opportunities that not only elevate the aesthetic appeal of their products yet additionally enhance manufacturing efficiency and reinforce customer involvement.

Material Choice

Product choice is an important aspect of mastering in-mold decorations, as it directly impacts the quality and durability of the last item. When picking materials for in-mold decors, it is essential to consider variables such as compatibility with the molding process, the preferred aesthetic end result, and the environmental conditions the product will deal with.

Furthermore, the picked product needs to have excellent attachment buildings to make sure that the decoration sticks firmly to the substratum during the molding procedure. Attachment between the decor and the product is critical for avoiding delamination and making certain long-lasting aesthetic allure. Furthermore, materials with high warm resistance are chosen for in-mold designs, particularly for items that will certainly be exposed to raised temperatures during their lifecycle. By carefully selecting the appropriate material for in-mold designs, producers can improve the total high quality and toughness of their products, meeting the expectations of both clients and end-users.

Design Innovation

An important consider advancing the area of in-mold decors is the continual expedition and execution of design development strategies. Design technology plays an important role in improving the aesthetic charm, capability, and total top quality of products made using in-mold decor processes. By including innovative style components, producers can separate their items on the market, attract consumers, and stay in advance of competitors.

One of the crucial facets of style development in in-mold decorations is the integration of elaborate patterns, textures, and graphics that were previously testing to achieve with typical decoration approaches. Advanced modern technologies such as 3D printing and digital layout devices allow developers to develop complex and in-depth styles that can be perfectly transferred onto shaped components. Furthermore, the usage of vivid shades, metal coatings, and special effects like gloss or matte textures can further elevate the visual appeal of in-mold embellished items.

Furthermore, style innovation extends past aesthetics to include functional enhancements such as ergonomic shapes, incorporated attributes, and customizable aspects that satisfy details customer demands. By embracing style innovation, suppliers can unlock new possibilities for personalization, product, and imagination differentiation in the affordable landscape of in-mold decors.

Manufacturing Performance

Effective manufacturing procedures are vital for equating the ingenious designs created in the field of in-mold decors into top quality ended up items that meet market demands and customer assumptions. In the world of in-mold decorations, production performance includes numerous crucial elements that add to the general success of the manufacturing process.

In addition, carrying out automation and robotics in the manufacturing line can significantly boost efficiency by streamlining recurring jobs and decreasing the margin of error. Automation not only speeds up the manufacturing process but also enhances accuracy and repeatability, resulting in a more uniform and high-grade output. In addition, adopting lean manufacturing concepts, such as just-in-time stock management and waste reduction approaches, can additionally boost manufacturing effectiveness by lessening downtime and maximizing source use. In general, an all natural approach to production effectiveness is critical in taking full advantage of the potential of in-mold decoration techniques and accomplishing ideal outcomes in the affordable market landscape.

Quality Assurance Procedures

What are the key strategies read this for guaranteeing rigid quality control procedures in the world of in-mold designs? Quality control steps are paramount in in-mold design procedures to make certain the production of top notch and remarkable finished items. One critical approach is the application of strenuous inspection methods at every phase of the manufacturing procedure. This includes conducting thorough visual evaluations, dimensional checks, and color consistency evaluations to identify any type of incongruities or defects beforehand.

Making use of innovative modern technologies such as computerized examination systems can likewise enhance the high quality control process by offering accurate and trustworthy information for evaluation. These systems can find flaws that might be missed by manual assessments, thus improving general item top quality and uniformity.

Routine training and development programs for staff members associated with the in-mold design process can also add to maintaining high-grade requirements. By enlightening team on best techniques, top quality assumptions, and the relevance of interest to information, companies can promote a culture of top quality consciousness throughout the organization.

Customer Charm

To boost the marketability of in-mold decoration items, catering and recognizing to consumer choices play an important duty in determining their allure and success. Customer charm in in-mold decors is influenced by numerous factors, consisting of design looks, shade choices, sturdiness, and total functionality. Consumers are increasingly looking for customized and unique items that show their individuality and style. For that reason, providing customization options such as personalized designs, shade variants, and textural aspects can dramatically boost the appeal of in-mold design items.

Verdict

In-mold decors offer a versatile and efficient means to improve product looks. By meticulously choosing products, accepting cutting-edge designs, maximizing production processes, executing high quality control measures, and focusing on consumer charm, producers can attain optimum outcomes. It is essential for companies to consistently adjust and improve their approaches to remain competitive in the marketplace. In-Mold Decorations. Mastering in-mold decors needs an all natural approach that takes into consideration all aspects of the manufacturing process to make sure success.

In the world of manufacturing, the art of in-mold designs stands as a pivotal facet of item style and production. Layout development plays a critical duty in this contact form improving the visual allure, performance, and overall high quality of products made making use of in-mold design processes.One of the essential aspects of design technology in in-mold decors is the assimilation of useful reference detailed patterns, textures, and graphics that were previously testing to accomplish with typical decoration methods.Effective manufacturing procedures are important for equating the ingenious layouts developed in the area of in-mold decors into high-grade finished items that satisfy market demands and customer assumptions. Offering customization options such as tailored layouts, shade variations, and textural components can significantly boost the allure of in-mold decor items.